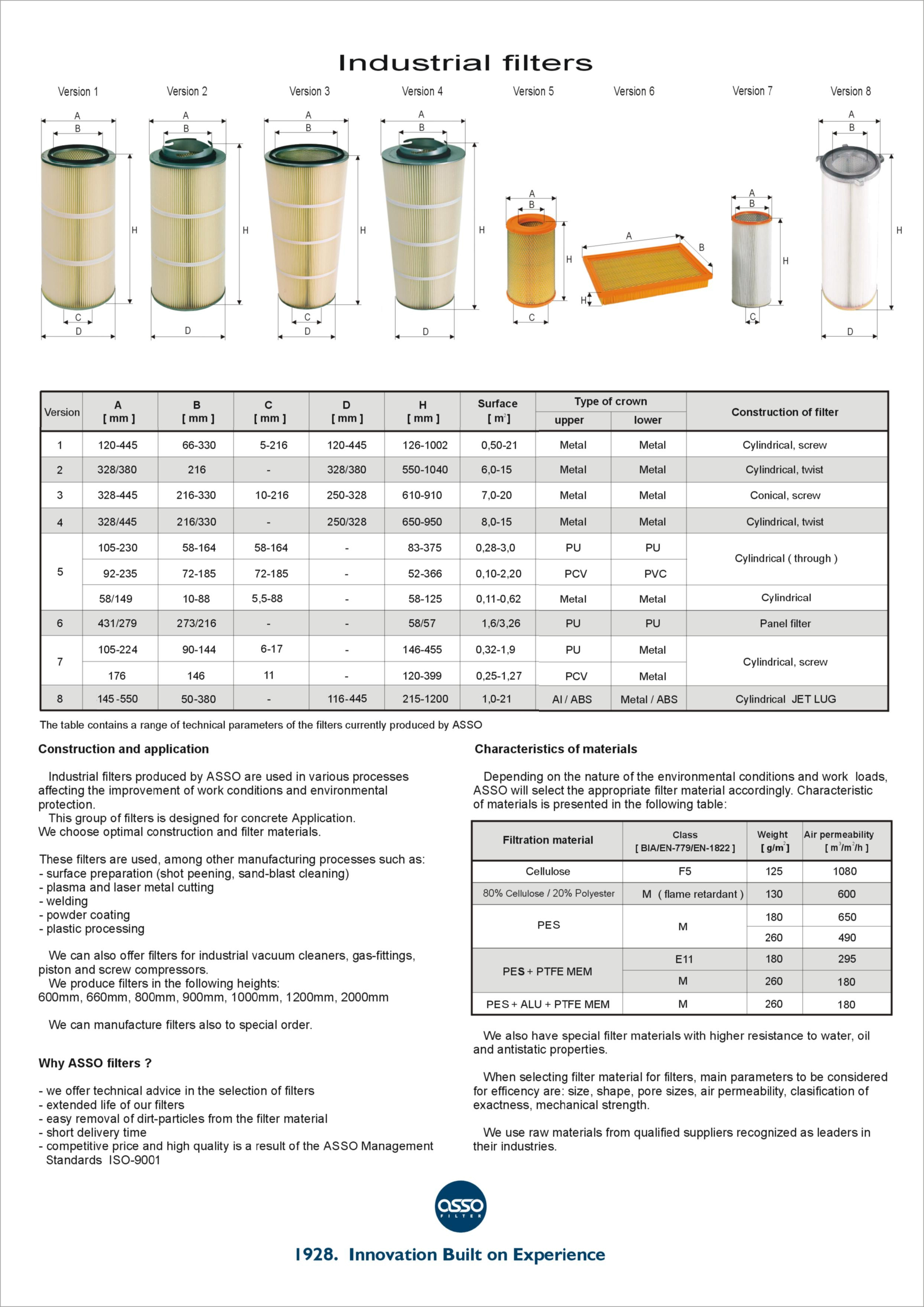

Industrial Filters

The majority of our industrial filters are for applications which use DRY filtration.

Made from a variety of materials and constructions, our air filter cartridges enable the clean and efficient operation of many complex production processes, such as:

- powder painting – technical description

- PROMAL

- GWO-MAL

- WOLMAL

- ZUGIL

- hot peening, sandblasting, glass bead blasting – technical description

- plasma cutting, laser cutting, torch cutting – technical description

- welding and grinding – technical description

- KLIMAWENT

- KLIMASERW

- BYSTRONIC

- KEMPER

- NEDERMAN

- MECHANIC SYSTEM

- machining of metals and plastics - technical description

- filtering - technical description

- Oval cartridges for DONALDSON filters

- Flanged cartridges ProTec, SOMOS

- Cartridges with threaded fastening RD58 / RD60 / RD72 / RD100

- Cartridges CPB / CPLPB Pleated Bags for the cement industry

- CS Dustmaster stationary cartridges for the wood industry

- Cartridges with axial seal CJ Steck

- Cartridges FMC Nederman, Dantherm

- Cartridges for dryers Piovan, Moretto

- Cartridges for compressors and vacuum pumps Becker, Rietschle, Solberg

- Customized cartridges, built to order (per customer designs or drawings)

- oil mist separation - technical description

- pouring and applying powdery substances - technical description

- production of compressed air - piston and screw compressors - technical description

- KAISER

- AIRPOL

- production of industrial gases - air intake - technical description

- electricity generation - gas turbines - technical description

- cleaning of production surfaces - industrial vacuum cleaners - technical description

- DISAN

- ENKE

- KEARCHER

- ERFOLG

Our products are offered under the “ASSO Filter” brand as well as the brands of distribution partners, including sales for the needs of the OEM market, in Poland and abroad.

Our products can be used successfully in the devices of such companies as:

- ANTICOR

- SCITEEX

- BEMAKOR

- GETRASUR

- PRODMOREX

- SZATKOWSKI

- SCHLICK

- SUDRA

- PLYMOVENT

- OMSG

- TEKA

- STEM

Please inquire if you require a filter cartridge that is not in our catalogue. We have our own tooling department and are generally able to respond to new product requests within a few days.

For all inquiries, please contact our sales department and we will do our best to assist in meeting your needs.

We would be pleased to partner with you and look forward to your inquiries !

Ask a question: